With vibration/stirring devices, preventing stored garnet from agglomeration or stuck in the system.

Online feeding of the abrasive without stopping the machine.

Metered feeding by accurate control enables you to improve the abrasive use efficiency and save the abrasive cost(one of the biggest costs in waterjet cutting operation).

Monitoring the abrasive feeding status in real-time allows you to adjust the feeding rate to the need.

Waterjet cutting head is one of key sub-systems of waterjet machine, as it convert high pressure water flow to high speed cutting jet with consistency. Cutting head has a lot more to do with the cutting performance(precision, cut speed and up-time).

Controlled axes: (Centering AC 5-axis) 5-axis linkage (AC);

Control accuracy: A, B = 5 arc seconds;

Control angle: A = ±75°, C = ±360°.

To separate abrasive from the water during cutting, through gravity settling, centrifugal effect and filtration etc.

It allows you to have the flexibility of adding devices to mobile pump unit for handheld cutting, linear cutting, circular cutting and other cutting mode.

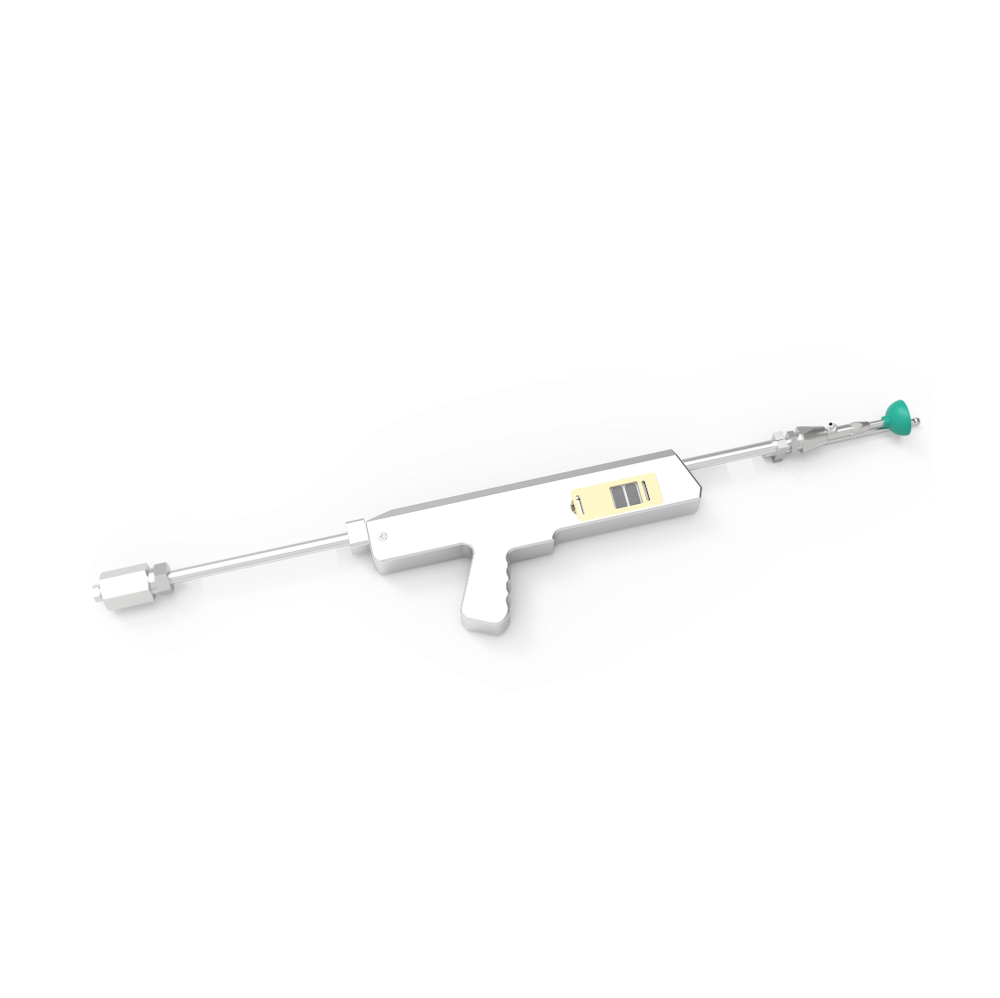

The handheld actuator integrates the ultra-high pressure water jet cutting capability into the handheld device, achieving flexible movement and precise control of industrial grade cutting operations.

The portable actuator expands the application boundary of high-pressure waterjet in non fixed locations through lightweight, modular, and wireless control design.

[Function]:

During the cutting, the pressure sensor on cutting head detects the gap between front end surface and workpiece and sends back the signal to the linear motor on the cutting head dynamic carrier so it can follow the shape and deformation of the workpiece with adjusted cutting target gap between workpiece and cutting head.

It is especially suitable for scenarios where there is a lack of workpiece size data, the workpiece is greatly deformed, and the robot trajectory programming cannot be accurately performed. Only an approximate cutting trajectory needs to be given, and effective cutting can be completed through the dynamic cutting head.

Features of the Cutter Head Follow-Up Mechanism

utilizing workpiece shape following by contact type, it is anti-interference, anti-drift, anti-temperature sensitivity etc., delivering stable performance in harsh operating environments.

Real-time pressure detection maintains the distance between the cutting head and the workpiece surface, dynamically adjusts the cutting head height, and ensures cutting quality.

The hollow pressure sensor is used to detect pressure coaxially with the TCP , making the detection more accurate.

The sensor and cutting head are coaxially designed with compact structure, which can better protect the nozzle and prevent splashing.

Ball screw and guide rail directly connected/driven by servo motor provides accurate and fast-response cutting head movements.

Fit for all brands of robots.

The backpack abrasive hopper is a key component of high-pressure waterjet mobile operations,used for delivering abrasive stably.

Increased mobility and comfort thanks to flexible protective material, new design, stretch fabric and pre-bent knees on the trousers. Full front protection as well as round the neck, shoulders, and the entire area round the forearm.

Water jet Gloves with protection up to 500 bar/7 500 psi.Separate inner gloves in nylon for optimal comfort and washability.

Water jet Boots 3000 bar withstands “everything” within water jetting on account of its fixed aluminium gaiters.The gaiters are moulded and jointed, providing excellent comfort and mobility.The water jet Boots have chem resistant anti-penetration soles.

Head Protection 3000 bar is a comfortable water jet Helmet with a Visor and Hearing Protectors. All parts are tested up to 3 000 bar / 43 500 psi. The only helmet on the market that is tested for high water pressure. Hook strap that prevents the water jet Helmet from falling off in the event of an accident. Hearing Protectors reduce the noise level by up to 33 dB . The water jet Helmet is adjustable for optimal protection and fit. 3-point chin strap is included.

To be the global top brand waterjet company, with the craftmanship of scientific, rigorous and lean.

Copyright © 2025 Forplus Intelligent Equipment (Chongqing) Co., Ltd.