In on-site demolition operations in the construction industry, traditional blasting and mechanical demolition methods face challenges such as strict environmental protection requirements, insufficient operation accuracy, and high safety risks. Aiming at these pain points, we provided a customized ultra-high pressure water jet cutting solution for building demolition companies to achieve efficiency, safety, and environmental friendly demolition operations.

A building demolition company undertook a complex building demolition project, which involved the precise demolition of concrete and steel structures, and at the same time had to meet strict environmental standards to avoid dust pollution and noise nuisance. Traditional breaker and blasting methods could not meet the needs of refined demolition, and there was a potential threat of vibration to surrounding structures. The company urgently needed a low-noise, dust-free, high-precision demolition technology to ensure the smooth progress of the project.

We provide a complete set of ultra-high pressure waterjet cutting equipment and solution, the core equipment include:

1.Forplus1+N armored ultra-high pressure waterjet pump:

equipped with Forplus1+N 60K-6L waterjet intensifier pump to ensure convenient transfer and transportation of equipment and stable operation during long-term field operations.

2.Linear Cutters:

Two linear cutters for different cutting travel are driven by motors to move in controlled speed. Those cutters are attached to working surface by magnetic device to follow the shape of any surface and do the precision cutting.

3.Cutting Head Assembly:

The detachable design makes it easy to replace the orifice and abrasive mixing tubes, adapting to the cutting needs of different materials and improving work efficiency.

4.Continuous Automatic Abrasive Feeding System:

Maxium capacity of 200Kg, with low-level, empty-level and fault alarms functions to ensure the continuous and stable supply of abrasive.

5.Remote Control System:

With remote emergency stop function to improve operation safety.

1.Efficient Operation:

In actual demolition projects, CNC waterjet machines show excellent performance, including better efficiency over traditional technolies.

2.Precise Control:

Through magnetic attachment and remote control, precise cutting of complex structures can be achieved, avoiding damage to surrounding retained structures and reducing subsequent repair costs. At the same time, remote operation and automated design reduce the risk of personnel working in close proximity.

3.Meet Environmental Regulations:

No dust is emitted during the operation and the noise is controlled within environmental protection standards.

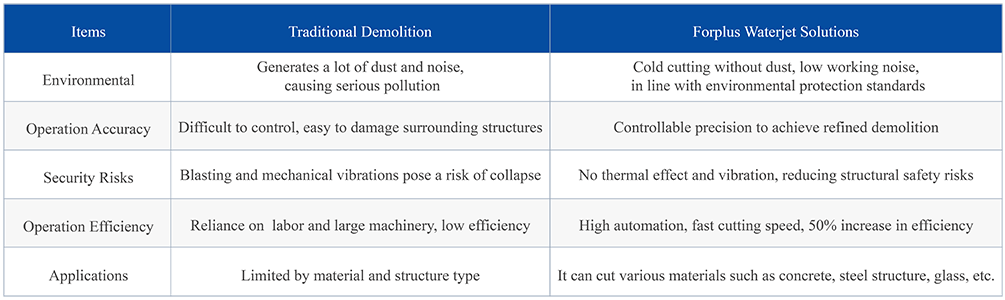

The application of Forplus waterjet in on-site demolition in the construction industry demonstrates the overwhelming superiority of ultra-high pressure waterjet technology in terms of environmental protection, precision, safety and efficiency. Through customized equipment configuration and advanced control systems, it provides a new green and efficient solution for the construction demolition industry. In the future, forplus waterjet will continue to deepen industry needs, promote the application of water jet cnc cutting technology in more construction scenarios, and help upgrade industry technology.

To be the global top brand waterjet company, with the craftmanship of scientific, rigorous and lean.

Copyright © 2025 Forplus Intelligent Equipment (Chongqing) Co., Ltd.