It has the advantages of no HAZ(Heat Affected Zone), high precision, high flexibility,3D capability and no pollution. There are various applications from different industries you can use it for, such as aerospace material processing, metal processing and automobile manufacturing, as well as stone, tile and glass.

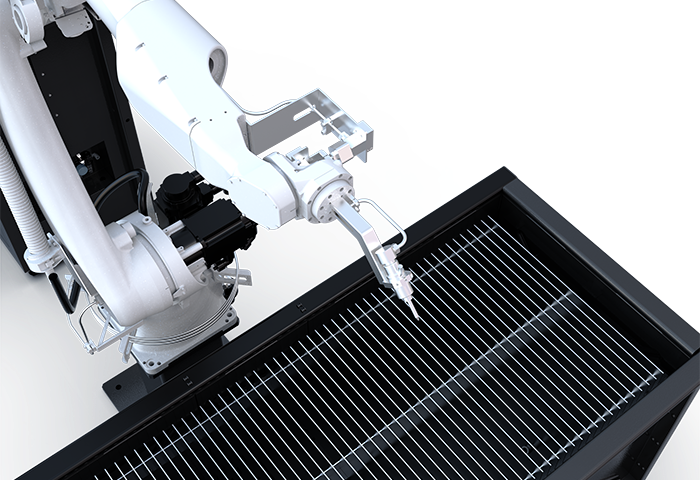

Redefines the modularity and flexible structure of high-pressure robotic waterjet cutting machines.

The hardware and software architecture design of the robot system is reconfigurable, scalable and adaptable, and can quickly respond to different task requirements or environmental changes through module replacement, parameter adjustment or functional reorganization.

Modularize your own water tank:

The overall tank size(width x length) can be configured and adjusted flexibly to the size and shape of your workspace. If you happen to work on some workpieces that are different from what usually would process (longer or wider etc.), you can adjust your water tank modules to your need. If you would increase your cutting envelope in the future, you can always add more modules instead of re-ordering a brand new big water tank.

Quick Setup:

Standardized connection interfaces between modules allow you to assemble and disassemble/re-arrange easily and fast. It is like a industrial “Lego” but provides robustness and precision.

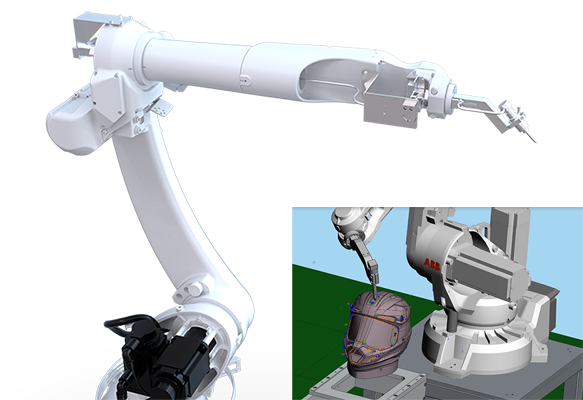

By adding 1-3 external additional axes to the standard 6-axis industrial robot, the cutting range can be expanded to achieve seamless cutting of oversized parts.

The automatic continuous abrasive garnet metering feeding system consists of standard continuous garnet feeding and quantitative garnet feeding tanks, achieving continuous online garnet feeding work and efficiently and accurately completing cutting operations.

To separate abrasive from the water during cutting, through gravity settling, centrifugal effect and filtration etc.

The position of the cutting head can be monitored in real time by a magnetic scale to correct cutting errors; or a high-definition camera or laser scanner can be used to automatically identify the contour of the workpiece and adjust the cutting path.

The offline programming function of high-pressure waterjet cutting refers to the pre completion of cutting path planning, process parameter settings, and other operations on a computer through dedicated software, generating processing programs that can be directly executed by waterjet cutting machines without relying on real-time on-site debugging.Offline programming would help you improve the efficiency and be able to cut parts of complex shapes.

Quickly generate models to optimize cutting paths and adapt to complex shapes.

To be the global top brand waterjet company, with the craftmanship of scientific, rigorous and lean.

Copyright © 2025 Forplus Intelligent Equipment (Chongqing) Co., Ltd.