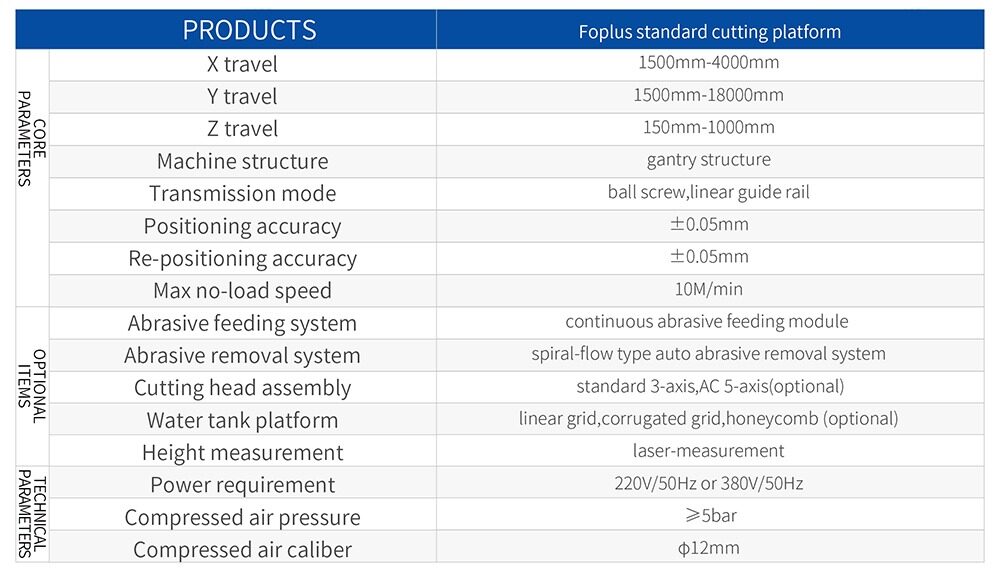

ForPlus 15/20/30 series Waterjet cutting machines, as classic waterjet XY platforms, are built to cut with precision, efficiency and reliability.

All sub-systems and key components are built in modules and ready to mount.

Easy to install, troubleshoot and maintenance.

Water/abrasive proof from dual protections on transmission system.

Heat treatment for eliminating stress. Robust and reliable, with long service life.

Equipped with a bus absolute encoder servo motor and a high-quality ball-screw transmission system.

Special coatings on water tank and XY beams, unparallel wear resistance and corrosion resistance in the industry.

Add-ons to your needs – roll-over table, water shield, submerged cutting water tank,modular tank, magnetic scale etc.

Waterjet cutting head is one of key sub-systems of waterjet machine, as it convert high pressure water flow to high speed cutting jet with consistency. Cutting head has a lot more to do with the cutting performance(precision, cut speed and up-time).

Controlled axes: (Centering AC 5-axis) 5-axis linkage (AC).

Control accuracy: A, B = 5 arc seconds;

Control angle: A = ±75°, C = ±360°.

The automatic continuous abrasive garnet metering feeding system consists of standard continuous garnet feeding and quantitative garnet feeding tanks, achieving continuous online garnet feeding work and efficiently and accurately completing cutting operations.

To separate abrasive from the water during cutting, through gravity settling, centrifugal effect and filtration etc.

The position of the cutting head can be monitored in real time by a magnetic scale to correct cutting errors; or a high-definition camera or laser scanner can be used to automatically identify the contour of the workpiece and adjust the cutting path.

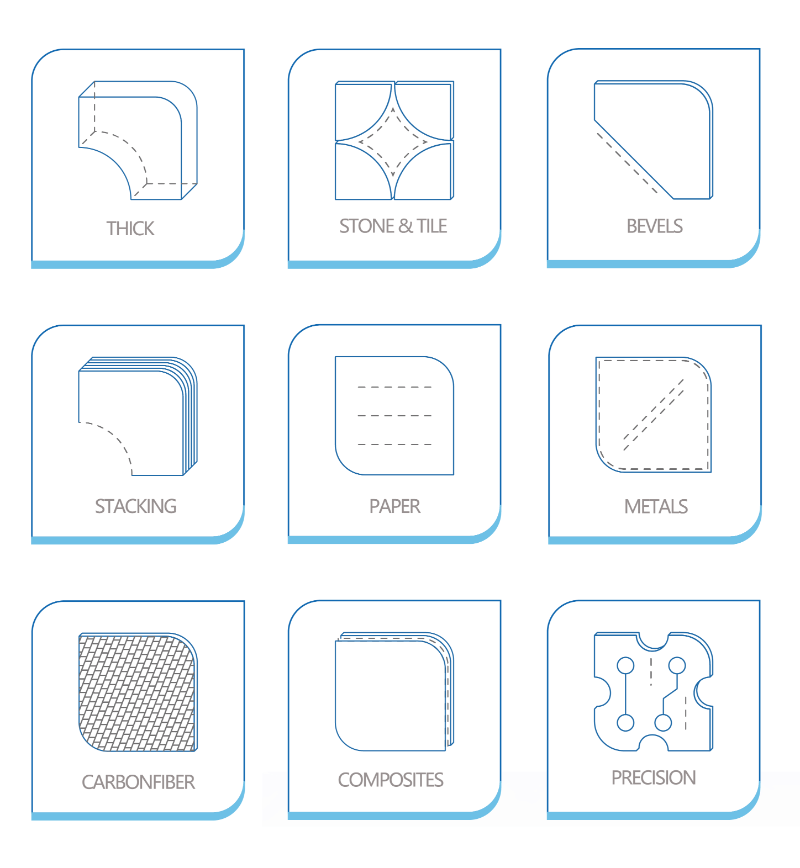

Standard XY Waterjet Cutting Machines are good for massive production of various of materials like alloy, stainless steel, stone/tile, composite, glass etc. with precision.

To be the global top brand waterjet company, with the craftmanship of scientific, rigorous and lean.

Copyright © 2025 Forplus Intelligent Equipment (Chongqing) Co., Ltd.