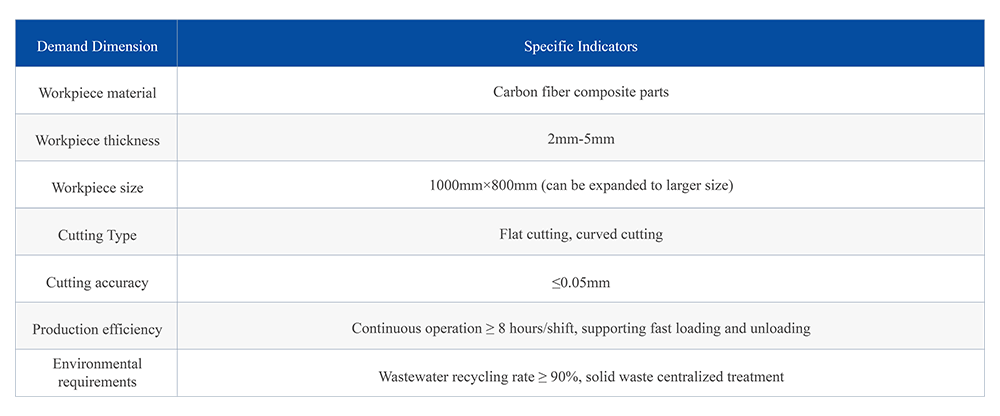

With the continuous growth in demand for lightweight materials in aerospace, high-end equipment and other fields, carbon fiber composite materials have become the mainstream choice due to their high strength and lightweight characteristics. However, their complex layered structure and high hardness characteristics pose severe challenges to the cutting process – traditional thermal cutting processes are prone to carbonization and stratification of materials, and high-precision curved surface cutting requires flexibility and stability. When developing new composite parts, an aviation manufacturing company urgently needs a set of diversified cutting solutions for 2-5mm thick carbon fiber parts, covering high-precision processing of flat and curved surfaces, and at the same time requires the equipment to have efficient continuous operation capabilities and environmental protection characteristics.

Technical Route: Cold cutting + flexible robot + intelligent system

In view of the characteristics of carbon fiber materials such as “fear of heat, shock and delamination”, ultra-high pressure water jet cold cutting technology is used to forplus waterjet cutting machine, combined with a six-axis robot flexible actuator to build a full-process intelligent cutting system.

1.Power System:

Equipped with a Black Panther 50Kplus high-pressure pump to avoid thermal damage to carbon fiber caused by traditional thermal cutting and ensure that the physical properties of the material are not affected.

2.Actuator:

An industrial six-axis small-arm robot is used to achieve arbitrary trajectory cutting in three-dimensional space through offline/teaching programming, accurately covering flat surfaces and complex curved surfaces.

3.Intelligent Auxiliary System:

Continuous abrasive feeding system + automatic abrasive removal system.

4.Customized Cutting Platform:

Customized modular, spliced expandable workbench, equipped with magnetic tooling, supports fast positioning and clamping, and reduces auxiliary time.

Advantages of the Solution

1.Precision Guarantee:

The water jet cutting seam is extremely small, and the robot’s precise trajectory control is combined to achieve the required cutting accuracy. The incision is smooth and burr-free, and no secondary processing is required.

2.Improved Efficiency:

Compared with traditional laser cutting, water jet cold cutting does not require frequent focus adjustment, and the continuous abrasive supply system eliminates downtime for abrasive replenishment, improving overall efficiency by more than 30%.

3.Material Adaptation:

The cold cutting process avoids problems such as resin carbonization and fiber peeling caused by high temperature in carbon fiber composite materials, and is especially suitable for the precise processing of multi-layer laminated structural parts.

4.Flexible Expansion:

Through offline programming software, the cutting path can be quickly switched to adapt to diversified product needs and shorten the new product development cycle.

The use of offline programming + industrial robots has greatly improved the application scope and cutting flexibility of water jet cutting, and has a wide range of application scenarios for the processing of new materials such as carbon fiber that are not suitable for laser cutting.

XY cutting:

The measured cutting accuracy and perpendicularity of the cut of carbon fiber plates meet the standards and meet aviation-grade assembly requirements.

Curved Surface Cutting:

For the parts with curved surfaces of the wing leading edge, Robot’s 7-axis coordinated motion (including external axis) is used to achieve smooth transition cutting, with a surface roughness of Ra ≤ 3.2μm.

We can provide customized upgrades for FORPLUS WATERJET according to the needs of different industries, such as:

1.Aerospace:

Integrate visual inspection system to achieve dynamic compensation of cutting path and adapt to complex curved surface cutting.

2.Automobile lightweighting:

Development of customized multi-axis water jet equipment to support batch cutting of carbon fiber parts for the entire vehicle, equipped with automatic loading and unloading robots.

3.Special Industries:

Explosion-proof water jet system, to meet the processing of composite materials in flammable and explosive environments (such as military and aerospace fuel tank components).

Forplus waterjet – empower composite material processing with water jet technology, and provide a new paradigm of green and precise waterjet cutting for high-end manufacturing.

To be the global top brand waterjet company, with the craftmanship of scientific, rigorous and lean.

Copyright © 2025 Forplus Intelligent Equipment (Chongqing) Co., Ltd.