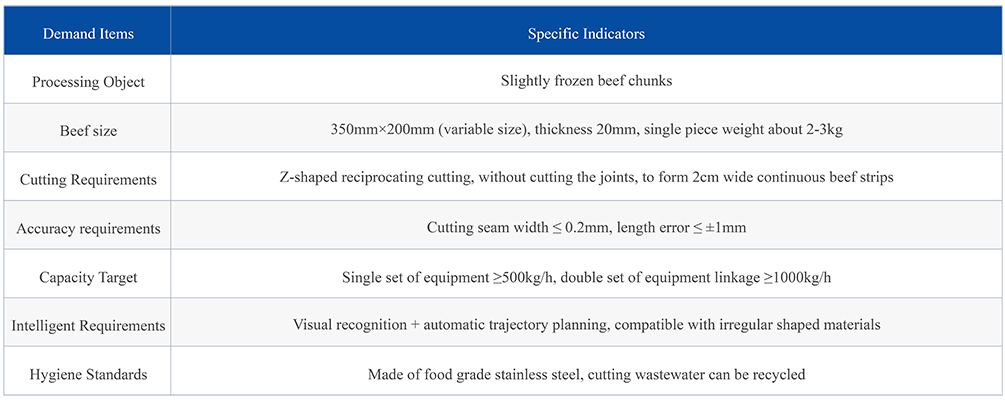

As the food processing industry is transforming towards automation and refinement, food processing companies are facing bottlenecks in the traditional cutting process during the production of beef jerky: manual cutting capacity is limited, and the cutting path of oscillating knife can not be programmed intelligently. , resulting in high cutting losses (about 15%-20%) and different size of finished products. The company urgently needs a high-precision cutting solution suitable for slightly frozen beef to achieve an upgrade from “manual extensive cutting” to “intelligent precision processing” to meet the annual production capacity requirements of thousands of tons of beef jerky, while reducing material losses and labor costs.

Technical Solution: pure water cutting + intelligent vision + 3-axis coordinated motion

In view of the particularity of food processing, we use ultra-high pressure pure water jet cutting technology, combined with visual recognition, conveyor belt loading and unloading and high-speed gantry three-axis system to build a full-process intelligent cutting solution:

1.Core Power:

It is a Panther series waterjet high-pressure pump, and uses food-grade stainless steel water circuit modification to ensure clean cutting water and extend the life of seals.

2.Actuator:

Customized assembly line three-axis gantry cutting platform, equipped with pure water cutter head, cooperates with automatic conveyor belt to enable “scanning-cutting” synchronous operation.

3.Intelligent System:

(1)Visual recognition module:

An industrial-grade camera scans the contour of beef in real time, generates 3D data and transmits it to the PLC, completing cutting path planning within 0.5 seconds.

(2)Coordination control technology:

The conveyor belt and the gantry axis interpolate to achieve cutting while conveying, and the cutting time of a each piece of jerky is ≤20 seconds.

(3)Hygienic design:

The cutting area uses a removable food-grade stainless steel baffle, waste water is recycled in real time through a negative pressure system, and the meat scraps separation efficiency is ≥95%.

Innovation of the Solution:

1.Advantages of Cold Cutting:

Pure water cutting has no thermal effect, thus avoiding the deterioration of beef protein and keeping the meat tender. The cut surface is smooth and free of debris, and does not need to be cleaned again.

2.Flexibility:

Compatible with various thickness materials, cutting specifications can be quickly switched through parameter adjustment, and you can save your most common used cutting paths to “customized cutting path database” to meet the production needs for multiple jerky categories.

3.Capacity Optimization:

Multiple-machine and multiple cutting heads in operation in parallel.

Cutting quality :

1.Accuracy Meets Standards:

The tolerances of kerf width/length are measured to meet the standardized production requirement of beef jerky, as well as other parameters.

2.Quality Assurance:

There is no charring or adhesion on the cut surface. Cold cutting reduces bacterial growth. Microbiological testing shows that the total colony count is 40% lower than traditional cutting.

Efficiency and cost optimization :

1.Improved Production Capacity:

Multiple sets of equipment are linked together to improve efficiency compared to manual cutting.

2.Reduced loss:

Cutting loss is reduced from 18% to less than 5%. 3.Labor Costs: One set of equipment only requires one operator, which is five fewer workers than traditional production lines.

Hygiene and Environmental Protection:

1.Safety material:

The main components of the equipment is made of 304 stainless steel with a surface roughness of Ra≤0.8μm, which meets FDA food contact standards.

2.Wastewater Treatment:

The recycling rate of cutting wastewater reaches 85% after cyclone separation, solid waste is collected and treated centrally, and the particulate matter content of wastewater discharge is ≤20mg/L.

“The water jet solution we added completely solved our pain points in beef cutting – intelligent trajectory planning greatly reduced losses, and the cold cutting process maintained the original flavor of the meat. After the two sets of equipment were put into production, our production capacity bottleneck was broken, and the cost of hygiene management was significantly reduced.”

—— Customer Production Manager

Forplus waterjet cutting machine can provide diversified solutions for the food industry.

High-pressure water jet cutting is suitable for cutting most boneless food materials, including various meats, aquatic products, fruits and vegetables, fats, oils, baked goods and chocolate. This solution uses conveying equipment with a high-speed gantry cutting space and can be applied to batch processing scenarios in most food processing factories. Combined with machine vision, the intelligence and automation of processing can be greatly improved.

In order to add intelligent equipment, the water cutting equipment can also be integrated into other food processing automation production lines to form a complete food production line with water cutting technology.

Forplus waterjett – empower the food industry with water jet technology, use cold cutting to protect the original taste of food ingredients, and provide global food processing companies with a new green and efficient intelligent cutting option.

To be the global top brand waterjet company, with the craftmanship of scientific, rigorous and lean.

Copyright © 2025 Forplus Intelligent Equipment (Chongqing) Co., Ltd.