Industrial scale of wind turbine blade recycling:

China’s wind turbine fleet began to be installed on a large scale after 2004. Given the 20-25 year lifespan of wind turbines , the industry will see its first wave of large-scale decommissioning in 2025, exceeding 1.2 GW and weighing over 10,000 tons of disassembly blades. By 2030, the nation’s wind turbine fleet is projected to exceed 10 GW, with over 10,000 turbines decommissioned and requiring approximately 200,000 tons of blades to be disposed of .

Data shows that by 2030, demand for blade processing will be approximately 30,000 tons, with a cumulative total of approximately 70,000 tons. ( Assuming that each blade weighs approximately 5-6 tons, the group is expected to process approximately 5,000 blades by 2030, with a cumulative total of approximately 12,000. This corresponds to approximately 2,000 wind turbine towers, with a cumulative total of approximately 4,000. )

Disadvantages of traditional cutting methods:

Currently, wind turbine blades are generally cut using traditional mechanical methods, such as angle grinders, circular saws, or wire saws . Although some companies are researching large-scale mechanized cutting equipment that uses large saw blades or circular saws for cutting, due to the characteristics of the material and process, most cutting is still done manually with handheld equipment.

Low efficiency:

Data indicates that a team of two to three people takes approximately 3 to 5 days to cut a single blade. The overall cost of cutting a single blade is between 2807.32-4210.98 USD . Furthermore, due to the inherent nature of manual labor and environmental factors , cutting efficiency is reduced.

Environmental pollution and dust problems:

From the perspectives of environmental protection and employee health, mechanical cutting should not be the primary method for large-scale wind turbine blade disassembly in the future. The cutting process generates a large amount of dust, which has a significant impact on the environment and human health. This dust, primarily composed of fiberglass, has a strong adhesive force that adheres to the skin and penetrates into pores, causing intense pain. Inhalation of this dust can have significant consequences for the lungs. Even when wearing protective clothing and dust masks during on-site cutting, inhalation of this dust is unavoidable.

The wind power industry is currently facing the challenge of replacing a large number of old and low-efficiency blades. These blades are long, so they must first be removed from the wind turbine tower using a specialized crane, placed on the ground nearby, and then initially cut. They are then transported by truck to a designated factory for further processing.

However, current manual cutting methods using handheld mechanical tools present numerous drawbacks that severely impact cutting efficiency. These include the remote location of the tower, a lack of access to water, electricity, and gas, and high labor and transportation costs. The customer demanded a comprehensive solution that maximized efficiency.

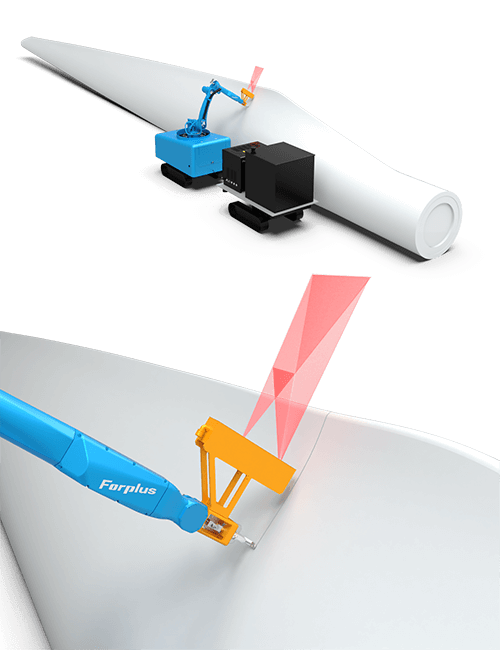

System skid-mounted solution: The core of the entire solution is a skid-mounted system, fully integrated into a standard container. It can be hoisted, transported, and used as a single unit. With sufficient energy and consumables, it can independently complete cutting operations.

The skid-mounted container is equipped with a power unit (generator set), a high-pressure pump, a water tank, an abrasive supply unit, and an air compressor. The generator set is fueled with diesel to provide power to the entire system. The water tank and abrasive are restocked with consumables and shipped to the site on the skid. Together, they deliver the high-pressure water jet’s cutting capabilities.

Cutting actuator: The cutting actuator is the core of the entire system. The ultra-high-pressure waterjet cutting action is completed by the robot on the actuator driving the waterjet cutting head.

Overall skid installation:

1. The cutting mechanism is carried by a custom crawler vehicle that can be moved remotely. Once the equipment reaches the operating location, the operator controls the crawler vehicle, which then exits the container and drives to the designated location for cutting.

2. Industrial robots The entire system uses a standard six-axis industrial robot as the actuator. This robot is now very mature and stable. Combined with a central control system and 3D vision assistance, it can effectively complete cutting operations.

3. 3D visual assistance The front end of the robotic arm is equipped with a 3D vision camera and runs our independently developed vision algorithm. It can complete various types of cutting on blades in an automated manner without the need for 3D digital models or programming.

Portable handheld cutting mechanism: As a supplementary device, the entire solution comes with a handheld high-pressure waterjet cutter . Used in conjunction with a skid-mounted high-pressure pump system, it provides convenient and flexible cutting. It’s ideal for cutting in specialized locations and is a great complement to automated cutting equipment.

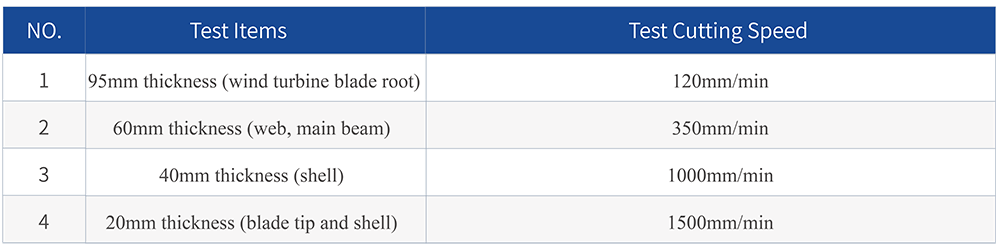

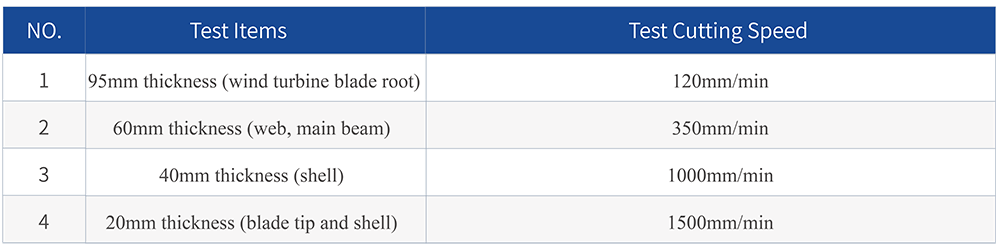

Cutting time and efficiency analysis:

The calculation is based on the following: Using a 1+N series high pressure, 6L/min high pressure pump, 0.4mm orifice, 380Mpa high pressure water pressure, and 80 mesh abrasive, test cutting was conducted on fiberglass wind turbine blade samples of various thicknesses:

Test data table:

Capacity estimation:

The above is an overview of the entire solution. As an intelligent, miniaturized, universal, skid-mounted waterjet cutting solution for high-pressure waterjet cutting of wind turbine blades, it offers numerous advantages, including high integration, wide adaptability, simple operation, and compatibility with practical scenarios in the blade industry.

To be the global top brand waterjet company, with the craftmanship of scientific, rigorous and lean.

Copyright © 2025 Forplus Intelligent Equipment (Chongqing) Co., Ltd.